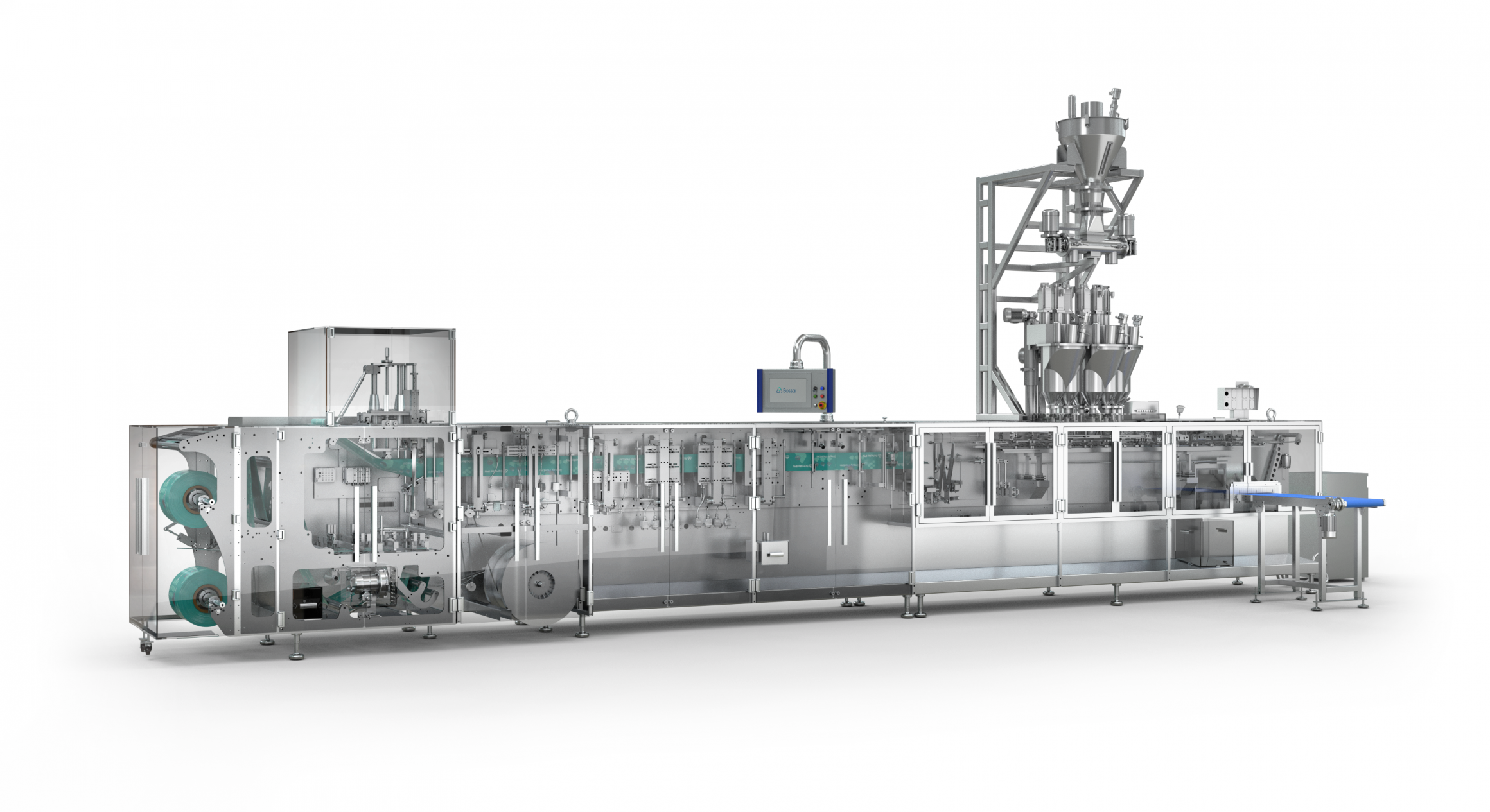

SIG Mechanical Series P-3300

Maximum Flexibility with modules

SIG Mechanical Series P-3300 forms and fills pouches within a range of 80 x 80 mm and 260 x 300 mm, it can reach an output of 120 pouches per minute and can fill up to 2,500 cc of product in simplex and 1,200 cc in duplex.

Dosing units for liquids available with different nozzles for any kind of product. Hygienic design and easy to dismantle filling system, with clamps. SIG HFFS machines are suitable to work with different kinds of dosing systems: volumetric dosing units, multihead weighers, piston pumps fillers, etc.

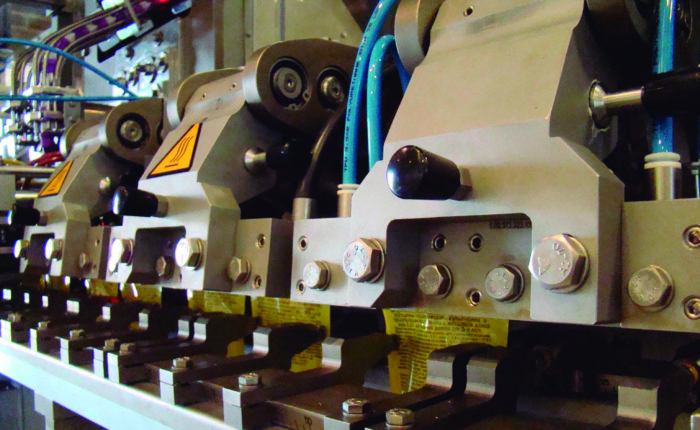

Vertical sealing group equipped with motorized size adjustment through touch screen. Sealing jaws temperature individually controlled.

Top sealing and cooling groups with 180º folding hinge for easy cleaning. Sealing jaws adjustments are not required during the change of the sealing bars. Removable walking beam allows a fast format change over.

Cutting device, gripper and servomotor film pulling system are automatically adjusted from the machine touch screen with only one touch, thus ensuring a quicker format change.

SIG Mechanical Series P-3300 Gallery.

Mechanical

Mechanical technology consisting of cams.

Walking beam

Traditional walking beam transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

Retort

Sterilization of premade pouches and film from reel by means of an autoclave. Retort machines are suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté.

Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

Mirror machine

Placing one standard machine in front of the other operating the opposite direction makes operating easier and reduces staff required to control them.

Pre-made pouches

Option to fill the different products in pre-made pouches supplied from a pouch feeder with great capacity.

-

Double film reel (up to 600 mm. diameter)

-

Pouch bottom perforators

-

Film tensioning and buffering system

-

Film splicing table

-

Servo-driven film unwind

-

Forming plough

-

Bottom seal

-

1st and 2nd vertical seal

-

Seal cooling plate

-

Photocell for print registration

-

Servo-driven film transport

-

Pouch cutting unit

-

Pouch opening & bottom blowing

-

1st filling station

-

2nd filling station

-

Pouch stretching station

-

Top seal

-

Cooling station

-

Rejected pouch discharge

Optional: Valves

-

Corner cutting die

-

Valve insertion

-

Valve seal

-

Valve feeder

Technical features

| Execution | Format range (mm) WxH | Volume max. | Speed up to | |||

|---|---|---|---|---|---|---|

| Minimum | Gusset | Maximum | Gusset | (c.c.) | (Pouches per minute) | |

| FLT-1 | 135 x 135 | - | 200 x 300 | - | 1050 | 60 |

| FLT-2 | 75 x 80 | - | 165 x 300 | - | 850 | 120 |

| STU-1 | 135 x 135 | 40 | 200 x 300 | 48 | 1500 | 60 |

| STU-2 | 75 x 80 | 20 | 165 x 300 | 48 | 1100 | 120 |

| Technical data | SIG Mechanical Series P-3300 |

|---|---|

| Transport system | Walking beam |

| Reel diameter | 600 mm |

| Reel width | 750 mm |

| Reel core | 76 / 152 mm |

| Filling stations | Up to 3 |

| Machine dimentions (L x W x H) | 8650 x 1405 x 2060 mm |

| Electrical consumption | 15 kW |

| Air consumption | 300 l/min |

| Electrical data | 200-480V / 50-60 Hz / N + G / 3Ph (others under request) |

| PLC | ALLEN BRADLEY / SIEMENS (others under request) |

| Noise level | <70 dB |

| Safety | CE Standards, OSHA |