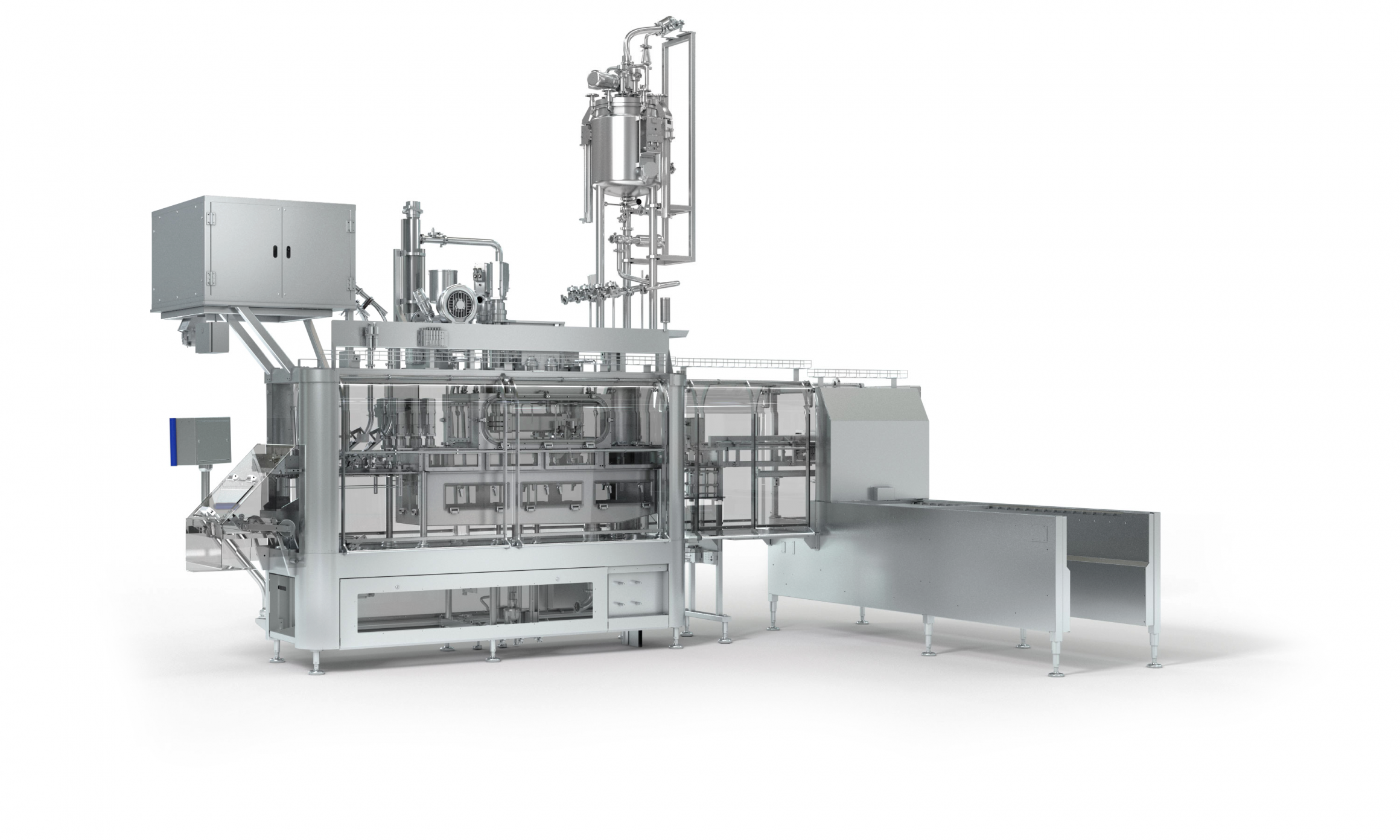

SIG CleanPouch 24

Compact, fast change-over and versatile machine for pre-made pouches

Filling through the spout for liquid products.

Advantages of filling through the spout:

- Higher filling level in the pouch, resulting in reduced head space and reduced film waste.

- With very liquid products there is less splashing occurring.

- Possibility of effective nitrogen flushing

Small footprint and high efficiency.

Food contact area: hygienic area designed for Food products applications.

Filling through the Spout. Presenting a series of advantages, such as as higher filling level/volume in the pouch, less film waste and head space. For very liquid products, less splashing occurs, maintaining the operation fast and clean.

Isolated food contact area. Due to its hygienic design, the SIG CleanPouch 24 is particularly devoted to Food Products.

Capping system. The machine can be quipped for conventional spouts with regular 8,5 mm diameter. And also feature an option for 10 mm.

SIG CleanPouch 24 in action.

SIG CleanPouch 24 Gallery.

Mechanical

Mechanical technology consisting of cams.

Walking beam

Traditional walking beam transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

Retort

Sterilization of premade pouches and film from reel by means of an autoclave. Retort machines are suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté.

Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

Pre-made pouches

Option to fill the different products in pre-made pouches supplied from a pouch feeder with great capacity.

-

Double film reel (up to 600 mm. diameter)

-

Pouch bottom perforators

-

Film tensioning and buffering system

-

Film splicing table

-

Servo-driven film unwind

-

Forming plough

-

Bottom seal

-

1st and 2nd vertical seal

-

Seal cooling plate

-

Photocell for print registration

-

Servo-driven film transport

-

Pouch cutting unit

-

Pouch opening & bottom blowing

-

1st filling station

-

2nd filling station

-

Pouch stretching station

-

Top seal

-

Cooling station

-

Rejected pouch discharge

Optional: Valves

-

Corner cutting die

-

Valve insertion

-

Valve seal

-

Valve feeder

Technical features

For technical information, please contact us at:

+34 93 729 77 30

info@bossar.com

| Execution | Format range (mm) WxH | Volume max. | Speed up to | |||

|---|---|---|---|---|---|---|

| Minimum | Gusset | Maximum | Gusset | (c.c.) | (Pouches per minute) | |

| BCF | 500 | 120 | ||||