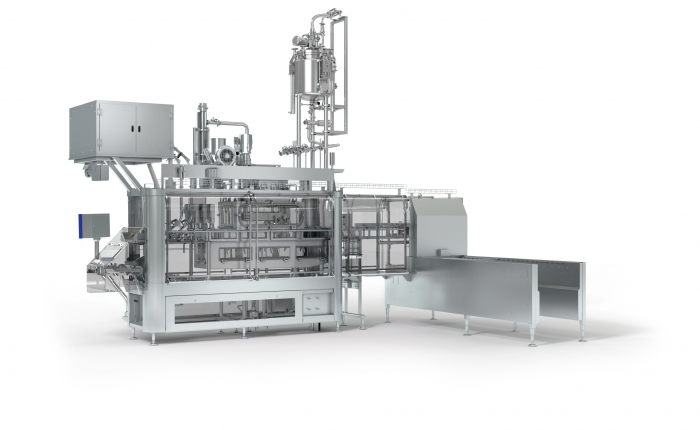

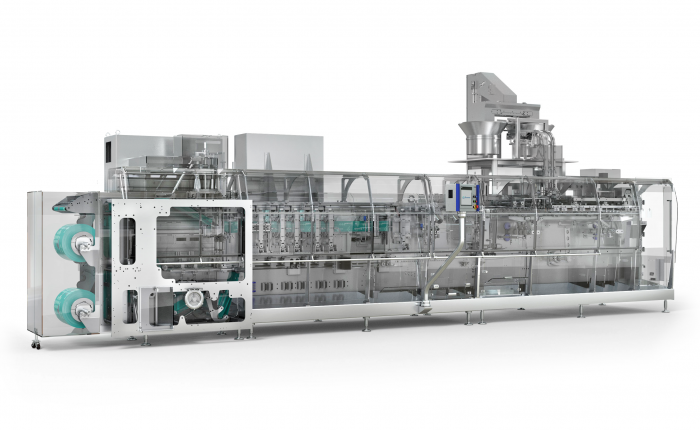

SIG Pouch Maker

More: Speed Quality Efficiency Shape pouches possibilities Changeover flexibility Less: Quantity of film Total cost of Ownership Energy consumption SIG POUCH MAKING MACHINE Horizontal Form & Seal machine. Highest quality spouted pouches. Increase speed and improve the quality without compromising on efficiency. For changeover flexibility with shaped pouches. By increasing the efficiency, and lowering the …