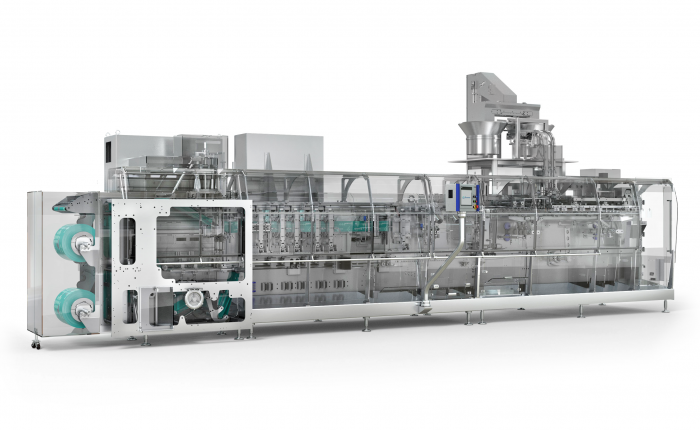

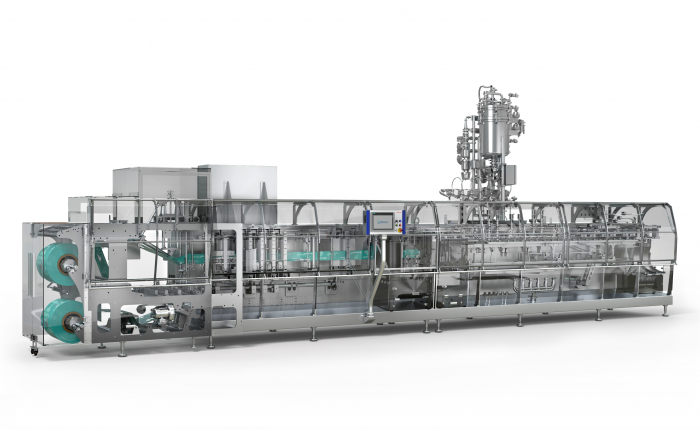

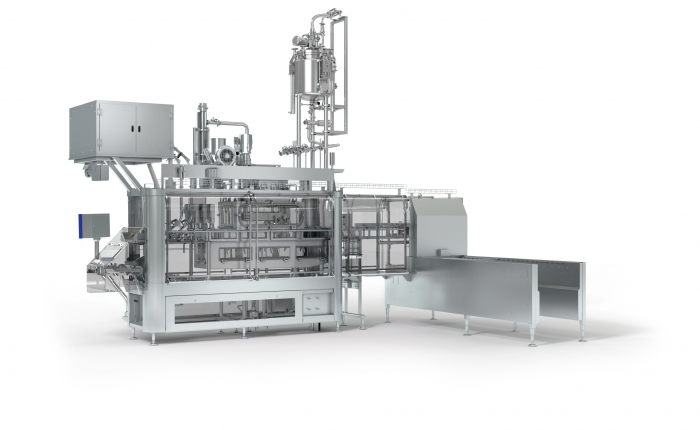

SIG has the widest range of Horizontal Form Fill and Seal machines in the market. Our machines cover all the applications and are customized to be adapted to our customers’ needs. Besides the traditional mechanical machines, we have the SIG Motion Series, the only complete Full Servo series in the market. The design is based on the modular frame construction, composed of three independent modules: unwinder, pouch forming and dosing-sealing. These modules are available in several versions according to the product to be filled. This way we always offer our customers the machines that suit better their requirements.

Pouches/sachets that are made using HFFS technology are less expensive than Pre-made ones.