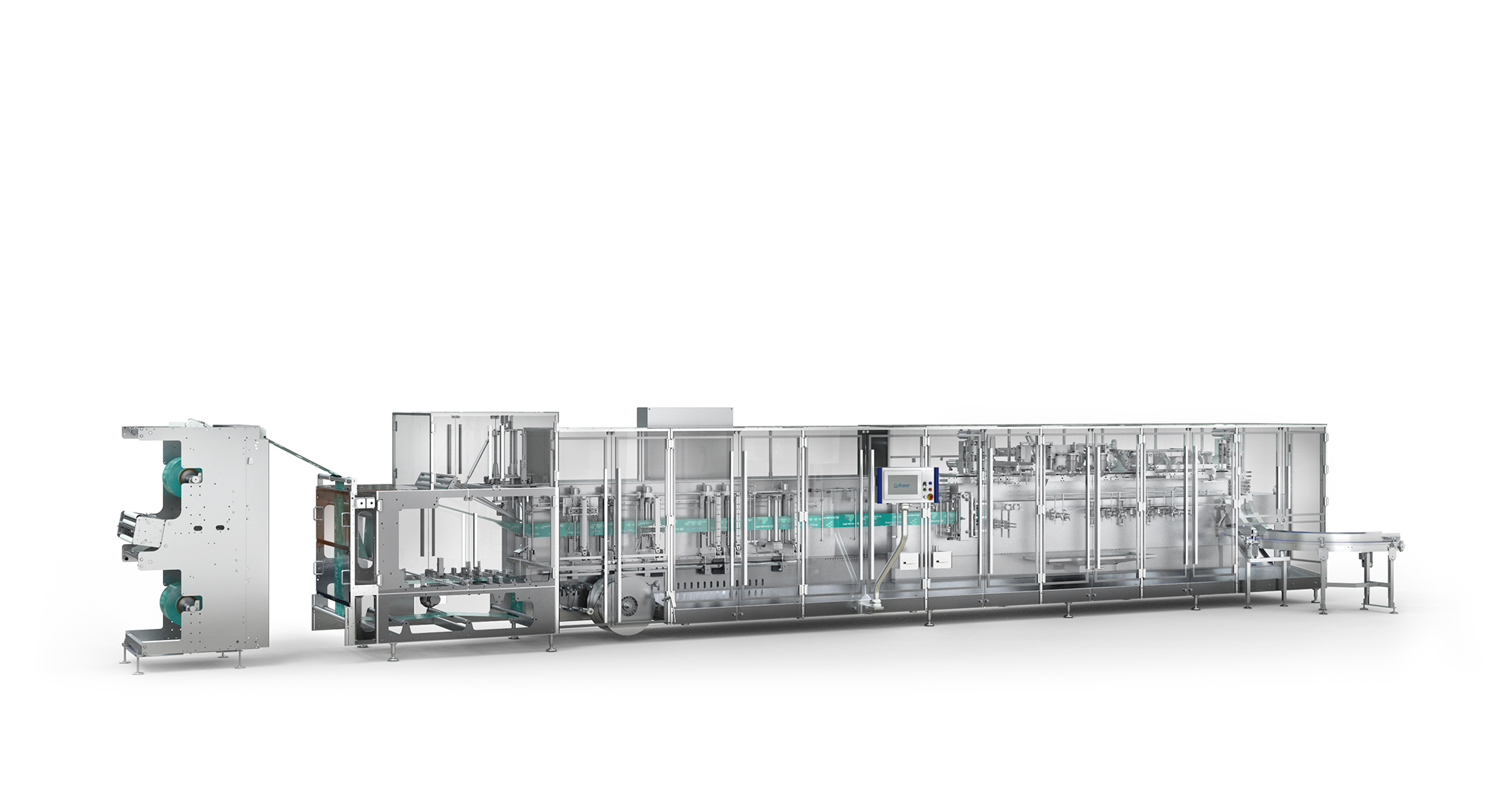

SIG Carousel System

Designed for big formats and quick change-over

Unique pouch handling system consisting in grippers holds them throughout the process. The grippers can be adjusted to a new format size in a matter of minutes by means of the HMI touch screen.

Both the pouch positioner and the grippers that hold the pouches during filling and sealing were designed and registered by SIG.

The SIG Carousel System fills and seals pouches within a range of 100 x 150 mm. and 300 x 400 mm. It can reach an outpout of 120 pouches per minute and can fill up to 6 liters of product.

Same clamps holding the pouch throughout the process.

SIG Carousel System in action.

SIG Carousel System Gallery.

Full servo motion

This smart servo-control system allows independent operation between the different stations, offers great reliability and little maintenance.

Carousel

The carousel transport system patented by Bossar is the ideal technical solution for heavy and large volume packaging formats. It consists of mechanical grippers assembled on a linear carrousel with intermittent motion that hold the pouches, keeping its position during the complete filling and sealing process.

Retort

Sterilization of premade pouches and film from reel by means of an autoclave. Retort machines are suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté.

Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

Mirror machine

Placing one standard machine in front of the other operating the opposite direction makes operating easier and reduces staff required to control them.

Pre-made pouches

Option to fill the different products in pre-made pouches supplied from a pouch feeder with great capacity.

-

Double film reel (up to 600 mm. diameter)

-

Pouch bottom perforators

-

Film tensioning and buffering system

-

Film splicing table

-

Servo-driven film unwind

-

Forming plough

-

Bottom seal

-

1st and 2nd vertical seal

-

Seal cooling plate

-

Photocell for print registration

-

Servo-driven film transport

-

Pouch cutting unit

-

Pouch opening & bottom blowing

-

1st filling station

-

2nd filling station

-

Pouch stretching station

-

Top seal

-

Cooling station

-

Rejected pouch discharge

Optional: Valves

-

Corner cutting die

-

Valve insertion

-

Valve seal

-

Valve feeder

Technical features

For technical information, please contact us at:

+34 93 729 77 30

info@bossar.com

| Execution | Format range (mm) WxH | Volume max. | Speed up to | |||

|---|---|---|---|---|---|---|

| Minimum | Gusset | Maximum | Gusset | (c.c.) | (Pouches per minute) | |

| STU-1 | 150 x 150 | 44 | 300 x 400 | 75 | 6000 | 60 |

| STU-2 | 100 x 100 | 32 | 140 x 230 | 44 | 750 | 120 |

| Technical data | SIG Carousel System |

|---|---|

| Transport system | Carousel |

| Filling stations | 2 |

| Machine dimentions (L x W x H) | 5570 x 3173 x 2112 mm |

| Electrical consumption | 24 kW |

| Air consumption | 700 l/min |

| Electrical data | 200-480V / 50-60 Hz / N + G / 3Ph (others under request) |

| PLC | ALLEN BRADLEY / SIEMENS (others under request) |

| Noise level | <70 dB |

| Safety | CE Standards |